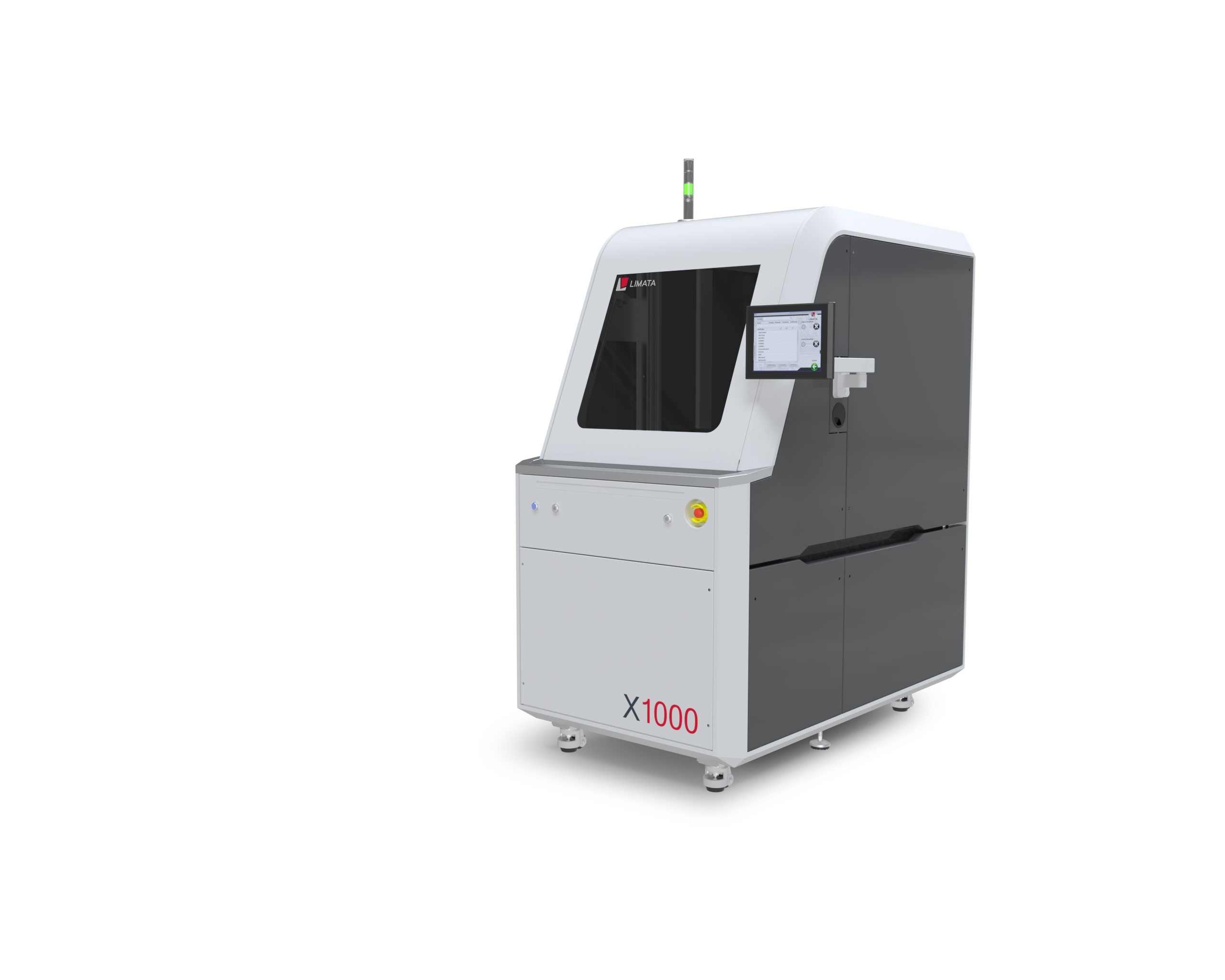

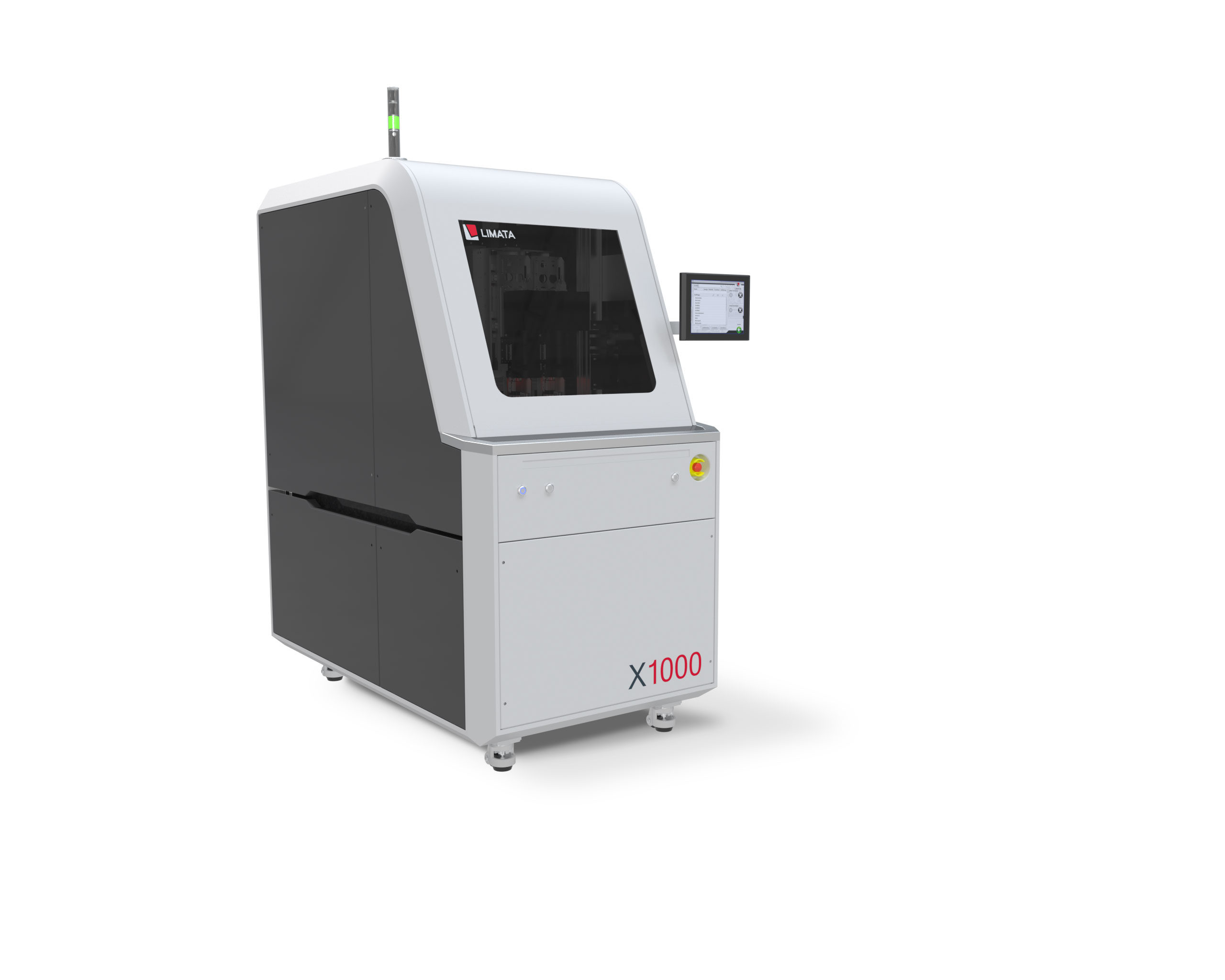

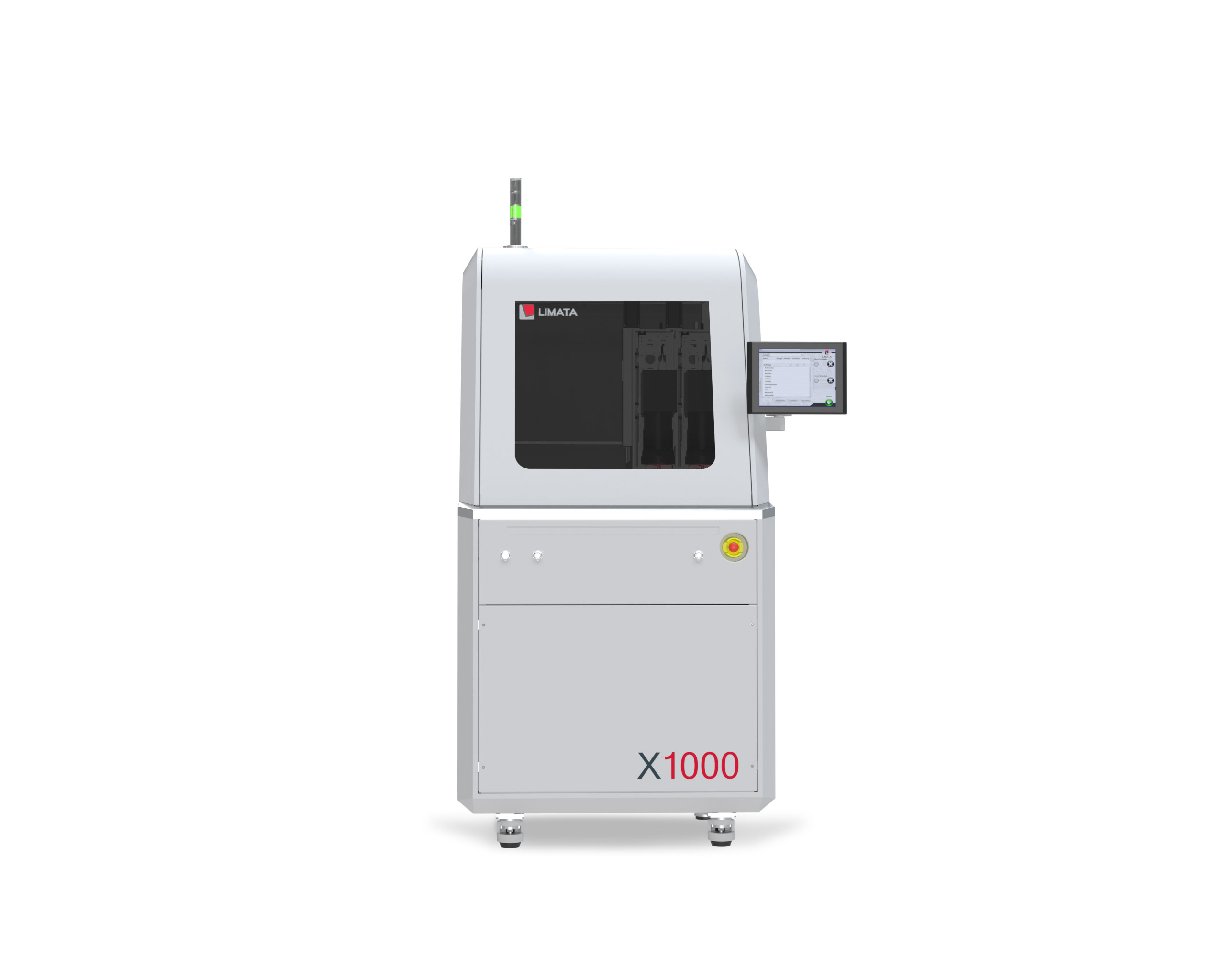

X1000

Universal and cost-efficient Laser Direct Imaging (LDI) system platform

designed for the flexible use in high-mix/low-volume PCB manufacturing environments during the dry-film patterning or solder mask imaging process

Description

The LIMATA X1000 series is a universal and cost-efficient Laser Direct Imaging (LDI) system platform designed for the flexible use in high-mix/ low-volume PCB manufacturing environments during the dry-film patterning or solder mask imaging process.

The new X1000 LDI system platform ensures maximum efficiency and throughput – i.e. from the use of LIMATA’s proprietary and in-house developed LUVIR (UV/IR) technology for solder mask imaging – at lowest possible TCO’s (Total Cost of Ownership) over the equipment life-cycle. Ideal for PCB manufacturers (or special PCB divisions of larger PCB makers) with high-mix/low-volume production mixes and imaging capacity/output requirements up to 500 panels per day (HDI, standard-rigid, flex) in a multi-shift operational mode. The use of LIMATA’s in-house developed LUVIR technology ensures competitive

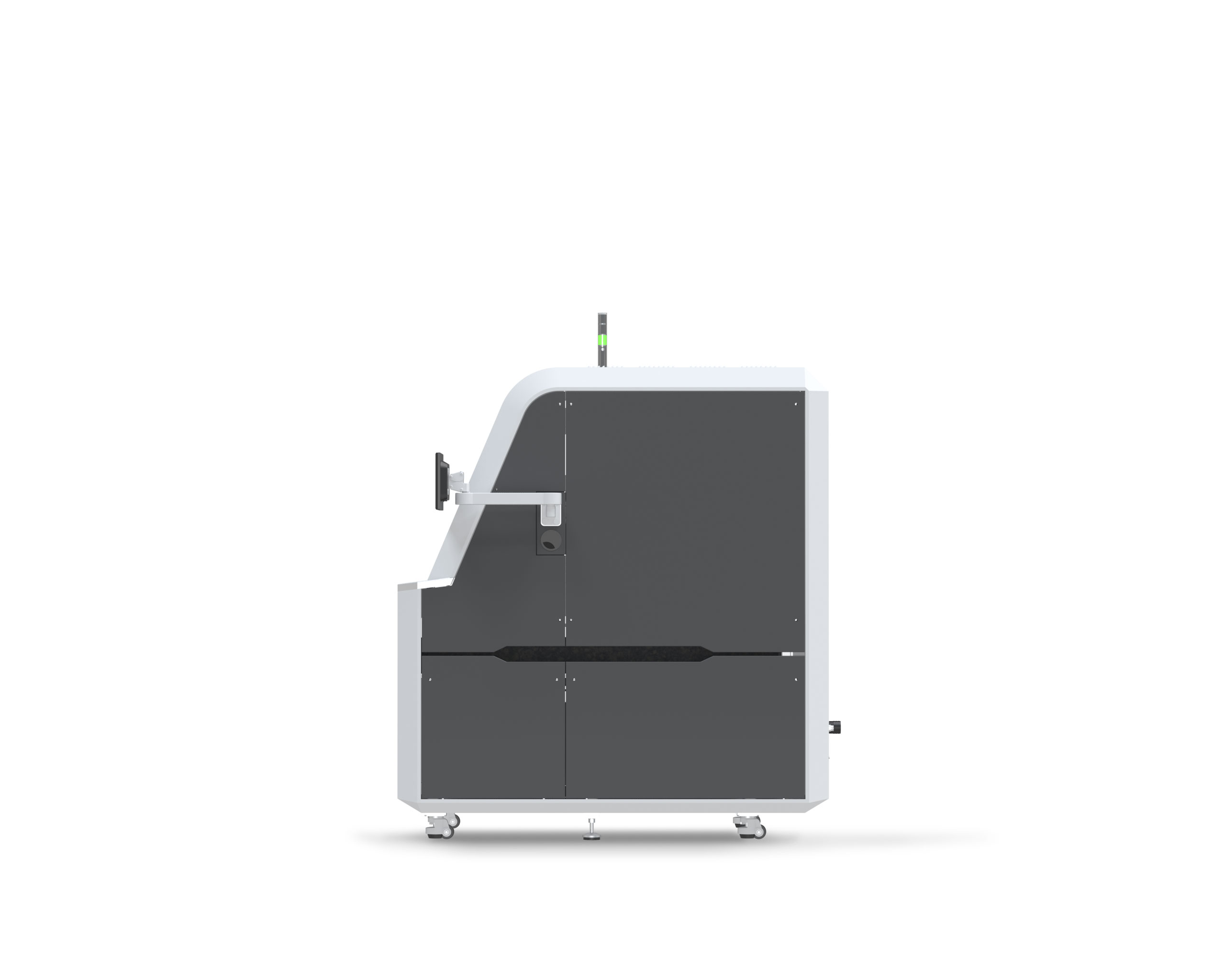

An optimized system operations footprint further provides for an easier placement and system movement within each facility.

Fully-integrated single and reel-to-reel automation (for flexible PCB’s) options can be provided upon request.

Key system features

- New flexible laser direct imaging platform for the maskless direct imaging of green, black, blue, white and red colored solder mask inks and dry-film resists (conventional and DI inks)

- NEW: Fully automated X1000A inline solution

- UV-laser set-up with >25.000 hours lifetime (MTBF)

- LIMATA’s proprietary and in-house developed LUVIR (UV/IR) solder mask imaging technology accelerates imaging speed on all standard / conventional solder mask materials, ensuring a continuous use of conventional ink types in the solder mask process (no requirement for DI inks)

- RGB & IR camera lightning for easy fiducial detection on all solder mask colors

- Laser mirror system with perfect power dissipation (no water cooling/ no power limitations)

- Highest optical depth of focus for an uniform power distribution on copper and base material

- Unique modular imaging head concept provides for in-field system capacity upgrades (additional imaging units or IR modules)

- Direct imaging capability on all conventional standard mask ink types (i.e. Tayio) at highly competitive throughput capacity levels

- Ease-of-use operator friendly data interface

- Designed to minimize maintenance, downtimes and service costs over the entire LDI equipment lifetime

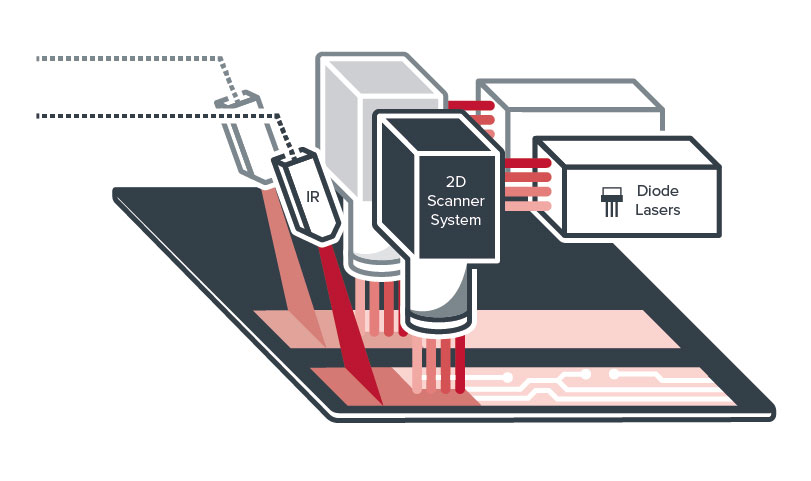

Laser and imaging technologies

- High-speed Galvo-Scan Laser Technology

- UV- diode laser set-up with 4/6 laser configurations per exposure unit

- IR-Module (for solder mask applications) / LUVIR Technology

- Highly telecentrical optical system

Modular laser direct imaging set-up

- Based on the specific solder mask ink type and color, energy levels (mJ/cm2) and direct imaging capacity requirements, the optimum UV-laser and IR-imaging Setup (ranging from 1 to 2 laser exposure heads and IR modules per system) can be selected and configured according to individual customer capacity needs

- Possibility to conduct in-field laser upgrades for increased imaging capacities (additional imaging heads and IR modules) enabled by a modular „plug-in” concept.

X1000 - Options

Adjustable laser spot size for advanced HDI production (High-Resolution)

Detection of multiple fiducials for maximum registration accuracy

Automated tracking of individual Barcodes or serial numbers for full product traceability

MES-interface and Secs/Gem programming options

(“real-time“ production data)

LDI Automation (Island of Automation / In-line)

The X1000 platform can be complemented by Limata´s own Inline automation solution X1000A in a single or twin configuration or a Reel-to-Reel (R2R) automation and handling system for Flex PCB’s.

PCB Applications

Standard PCB and HDI

- Standard (rigid)

- Standard (flex)

- Standard (rigid-flex)

- Any layer PCB

- mSAP (semi-additive)

Solder mask inks

(conventional and DI inks)

- Green

- Black

- Blue

- White

- Red