Description

The X2000 DF Series is LIMATA’s latest laser direct imaging system platform designed for the dry-film patterning of PCB inner and outer layers in medium to high-volume PCB production. Key target applications include standard rigid/flex, advanced (HDI) and custom PCB boards (i.e. thick copper automotive boards). Fully-integrated single and dual-system automation options for an Island of Automation or in-line LDI operation Setup can be provided.

Key system features

- Integrated dual table system as standard hardware feature for higher production efficiency and throughput levels (panels/h)

- Multi-wavelength laser set-up with >18.000 hours lifetime (MTBF)

- Highest optical depth of focus (+/-500µm)

- Unique modular imaging head concept provides for laser redundancy and in-field system capacity upgrades (additional imaging units)

- Direct imaging capability on all standard resist types (Hitachi, Asahi, etc.)

- Ease-of-use operator friendly data interface

- Designed to minimize maintenance, downtimes and service costs over the entire LDI equipment lifetime

Laser and imaging technologies

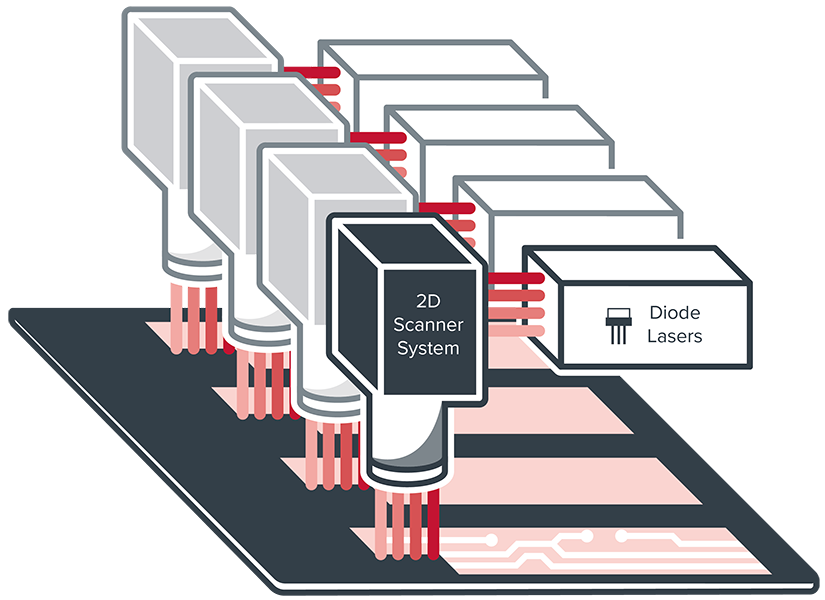

- High-speed Galvo-Scan Laser Technology

- UV-Multiwave diode laser set-up including three different wavelenghts

- High-telecentrical optical system

Modular laser direct imaging set-up

- Based on each customer‘s PCB specification, L/S resolution and direct imaging capacity requirements, the optimum laser imaging Setup (ranging from 1 to 4 exposure heads with up to 6 diode lasers each) can be selected and configured according to customer needs

- Possibilty to conduct in-field laser upgrades for increased imaging capacities (additional imaging heads) enabled by a modular „plug-in“ concept

Imaging and Software options

Adjustable laser spot size for advanced HDI production (High-Resolution)

Detection of multiple fiducials for maximum registration accuracy

Automated tracking of individual Barcodes or serial numbers for full product traceability

MES-interface and Secs/Gem programming options (“real-time“ production data)

LDI Automation (Island of Automation / In-line)

PCB Applications (dry film patterning)

Standard PCB and HDI

- Standard (rigid)

- Standard (flex)

- Standard (rigid-flex)

- Any layer PCB / mSAP (semi-additive)

Thick copper PCB applications

- IMS

- DCB (direct copper bonded)

Available system configurations (dry film patterning)

X2000 DF Standard PCB set-up

- Direct imaging (patterning) of Rigid / Flex and

HDI applications

X2000 DF Custom PCB set-up

- Direct imaging of Thick copper PCB applications (i.e. automotive / industrial)

- Customized system features include:

– Customized XY Gantry system

– Customized vacuum table

X2000 automation options

- Single LDI robot-automation

- Dual LDI robot-automation

X2000 automation options

- Single LDI robot-automation

- Dual LDI robot-automation